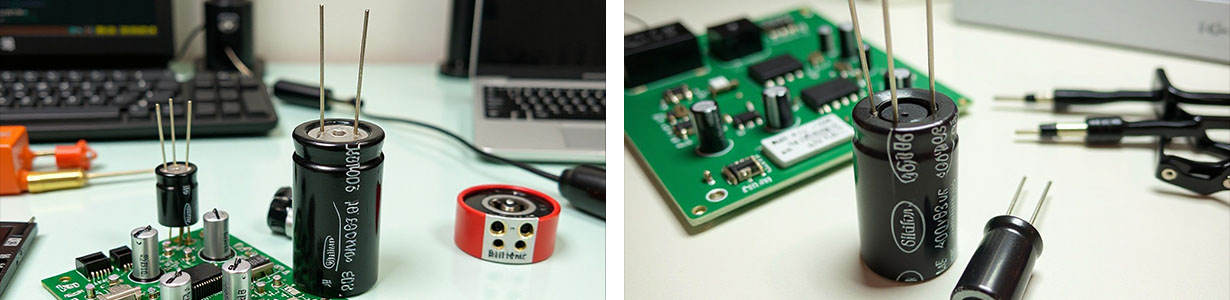

In the fast-evolving world of electronics, where devices demand greater miniaturization and reliability, the role of high-performance passive components is more critical than ever. Our factory is proud to announce significant advancements in our SMD (Surface-Mount Device) Aluminum Electrolytic Capacitor line, engineered to meet the rigorous demands of next-generation applications.

Traditionally valued for their high capacitance in a compact volume and cost-effectiveness, aluminum electrolytic capacitors are indispensable for filtering, bypassing, and energy storage. A key challenge has been ensuring long-term reliability, especially under high-temperature or high-ripple current conditions. Our latest generation addresses this by adopting solid polymer electrolyte technology. This innovation replaces the conventional liquid electrolyte, virtually eliminating the risk of dry-out and leakage, thereby dramatically extending operational lifespan and enhancing stability under thermal stress.

Our production leverages sophisticated foil processing techniques. The anode foil undergoes precise electrochemical etching, creating a micro-roughened surface that increases the effective area by 7-8 times, allowing for higher capacitance in a smaller footprint. This is followed by a controlled forming process, which grows a uniform, robust aluminum oxide (Al2O3) dielectric layer on the foil surface, dictating the capacitor's ultimate voltage rating and reliability. We meticulously control these steps to achieve lower Equivalent Series Resistance (ESR) and higher ripple current handling capabilities.

Key benefits of our enhanced aluminum electrolytic capacitors include:

· Extended Service Life: Stable performance over a wider temperature range (-55°C to 125°C).

· Improved Reliability: Excellent resistance to mechanical shock and vibration, suitable for automotive and industrial environments.

· High Capacitance Density: Meeting the need for miniaturization without compromising on charge storage capacity.

· Optimized for Modern Manufacturing: Compatible with standard infrared or hot-air reflow soldering processes for efficient PCB assembly.

These capacitors are ideally suited for power supply units in 5G infrastructure, advanced driver-assistance systems (ADAS) in vehicles, and high-stability industrial control systems. By pushing the boundaries of material science and process precision, we continue to provide foundational components that empower innovation.

For more information on our full range of aluminum electrolytic capacitors, including specifications and application notes, please visit our product section or contact our technical sales team.