I. Main Characteristics

An electrolytic capacitor is a polarized capacitor that uses an electrolyte as its cathode (or anode). Its most notable feature is:

1. High capacity-to-volume ratio: At the same volume, it can provide a much larger capacitance than ceramic capacitors, film capacitors, and other types of capacitors (typically ranging from 1μF to tens of thousands of μF, or even higher). This is its most core advantage.

2. Polarized: Most electrolytic capacitors have clear positive and negative poles. Reverse voltage application will cause damage or even rupture. However, there are also non-polarized electrolytic capacitors, used in special AC applications.

3. Wide rated voltage range: Common voltages range from a few volts to several hundred volts, meeting the needs of most circuits.

4. Low cost: The cost per unit capacity is much lower than that of other high-capacity capacitors, with high cost-effectiveness.

5. Limited lifespan: The internal electrolyte will gradually dry out over time and with temperature, resulting in a decrease in capacitance and an increase in equivalent series resistance (ESR). Therefore, it has a "lifespan" parameter (such as 2000 hours at 105℃).

6. Higher ESR: Compared to ceramic capacitors, its equivalent series resistance is larger, and the high-frequency filtering performance is slightly inferior.

7. Leakage current exists: There is a small DC leakage current, which needs to be considered in some precision circuits.

II. Main Types

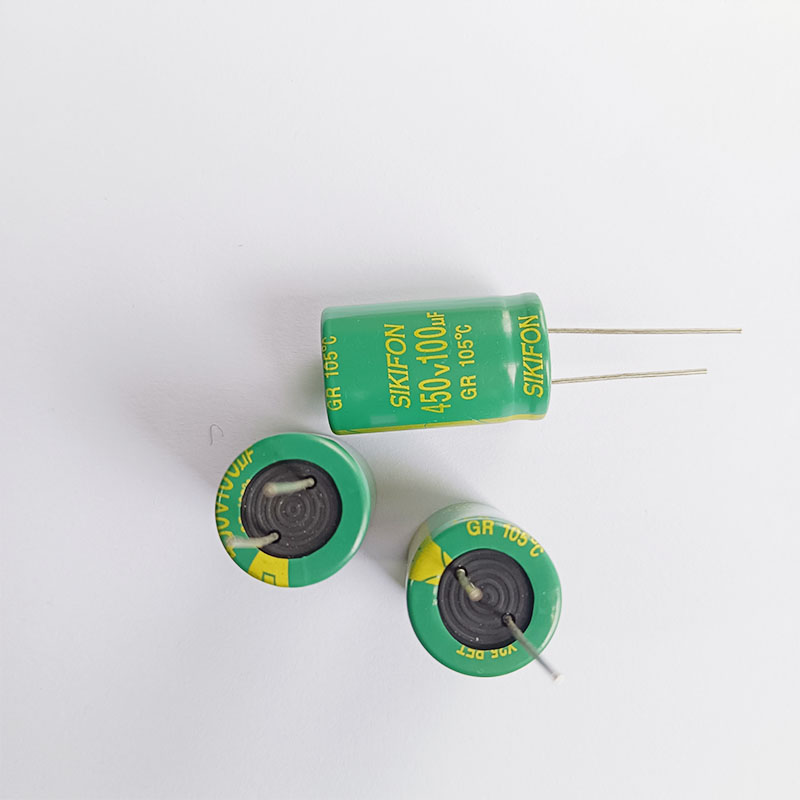

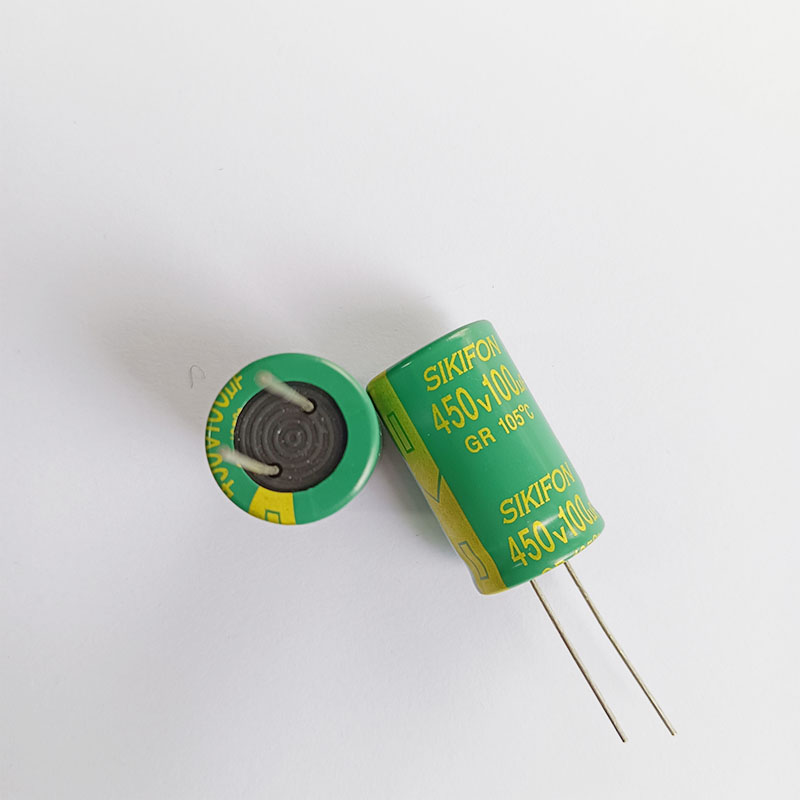

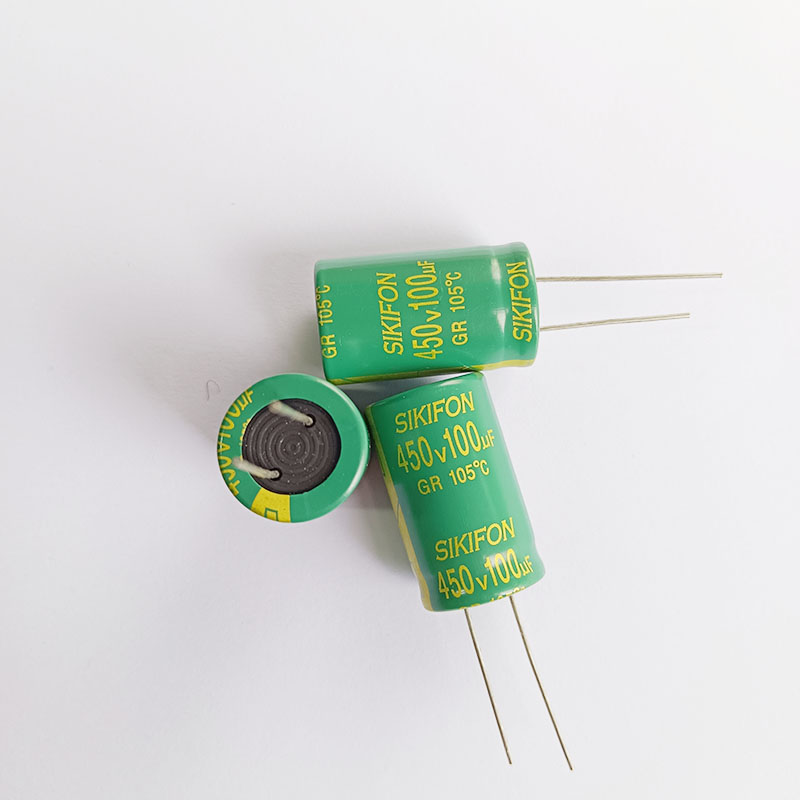

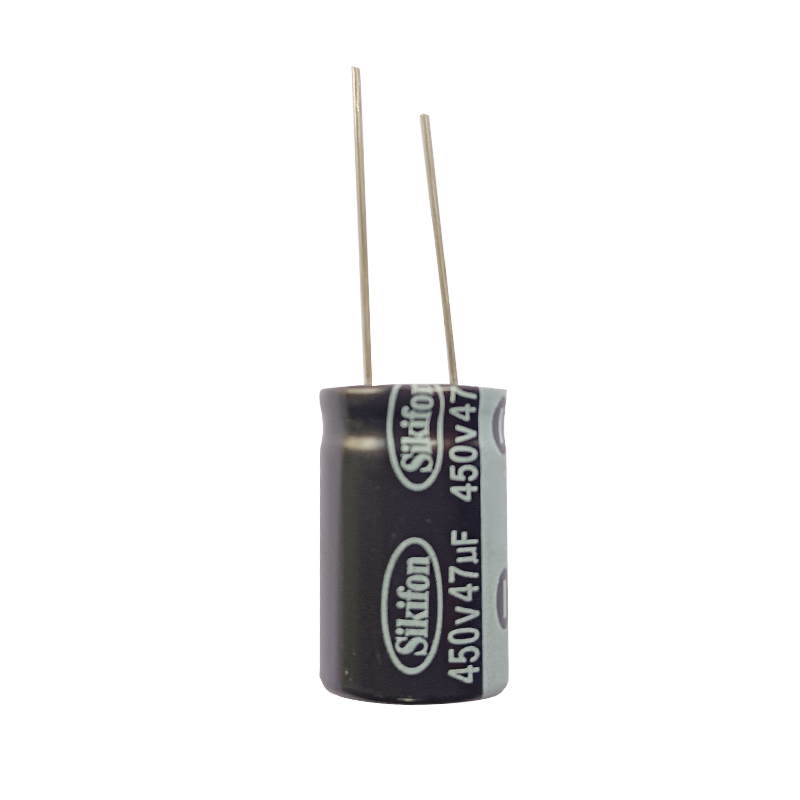

· Aluminum electrolytic capacitor: The most common type, with the lowest price and the widest application. It has a large capacity, but its lifespan and high-temperature performance are relatively average.

· Tantalum electrolytic capacitor: Uses manganese dioxide or polymer as the cathode. It is smaller in size, has a lower ESR, better stability, and a longer lifespan. However, it has weaker voltage and current shock resistance, is more expensive, and has the risk of short circuiting and catching fire (requiring circuit protection).

· Polymer capacitor (solid/combined): Uses conductive polymer as the cathode. It has an extremely low ESR, excellent high-frequency characteristics, an extremely long lifespan, and almost no leakage risk. It is a high-performance alternative to traditional aluminum electrolytic and tantalum capacitors, but it is also more expensive.

III. Main Applications

Due to its large capacity, electrolytic capacitors are mainly used for "energy storage" and "filtering" in circuits.

1. Power filtering/smothing: This is the primary application. After the rectification circuit, the pulsating direct current is smoothed into a stable direct voltage. For example, at the output and input terminals of a switching power supply (SMPS).

2. Coupling and decoupling: In amplification circuits, it serves as a coupling capacitor to block direct current and allow alternating current to pass; near the IC power pins, it is used as a decoupling capacitor to provide instantaneous energy to the local chip and suppress noise.

3. Energy buffering: In situations requiring large instantaneous currents (such as motor startup, flashlights), it provides backup power to alleviate the power supply's instantaneous burden.

4. Low-frequency filtering and timing circuits: Due to its large capacitance value, it is often used for filtering in low-frequency circuits (such as audio) and to determine the time constant of RC circuits.

Product Application